What's the present situation and future prospect for gantry tractors?

Present

July 2023 - further news of NEXAT

Things have moved on apace as far as NEXAT is concerned, with machines in Germany, USA and Brazil as well as many more in different stages of production. The recent video

produced by Farmworld.TV published in December 2022 shows just some of its capabilities with many more planned.

December 2021 sees a significant step forward in gantry development and technology

On the 7th December 2021, Kalverkamp Innovation announced the culmination of 5 years of development work in the form of NexAT - (NEXt generation Agriculture Technology). This 14 m span machine (18 m long on the road) is capable of low input tillage, planting, chemicals application and most importantly, harvesting of a range of crops including maize (as whole crop or separated grain) and small grain cereals. For more information and extensive video footage, visit the NexAT site.

It is nice to see that they have acknowledged work that Silsoe Research Institute undertook in the 1980s by including a video clip, the full version of which you will find on the history page of this site.

Other developments

In Brazil, a wide span vehicle has been designed as part of a "Minimum Impact Agriculture" project for growing and harvesting sugar cane for bioethanol production. Known as the ETC "traffic control structure", the research is being carried out by the Brazilian Ethanol S&T National Laboratory (CTBE). The manoeuvrability of the machine can be seen in this YouTube video

but the key aim of the research is to improve the smoothness of operation, whether this is in terms of the steering characteristics or the management of the traffic lanes. To date the research concludes that a stiffer tyre and lower weight have the greatest potential for increasing smoothness when driving on a specific track.

The ASA-Lift WS9000 mentioned on the History page

also still features. This video

taken in 2015 shows it elevating onions in the morning and a few hours later, cultivating using a completely different centre section. A further section is being developed as part of a slurry application system using an umbilical hose. This demonstrates that the two almost identical end units can be used as part of almost any spanning beam and associated implements.

An indication of the appropriateness of the design of a gantry tractor in delivering precision to operations is the plethora of autonomous vehicles based on its design, as reflected in the photos alongside. The wider the track gauge the greater the stability and the lower the tracked area.

In the Netherlands, a first move to a commercial wider track vehicle has been made by "MultitoolTrac". The company (started by a number of farmers in 2012) is now (late 2019) providing two electrically driven tractors with bio-diesel engine extenders and having an "on the fly" adjustable track gauge from 2.5 to 3.2 m. The machines have up to three hitches for implements together with power take-off drives. With all-wheel steer and drive combined with CTF, these vehicles will "punch above their weight" when it comes to output. They are a clever addition, responding particularly to the needs of vegetable producers and to the electric power market. Controlled traffic growers in the Netherlands using tractors extended to 3.2 m track gauge have always had difficulty moving their equipment on public roads. MultitoolTrac will overcome this as well as the rather alarming bending of locally extended axles!

Future prospects

The future prospect for gantry tractors has never been better! We are now realising just how much damage we are doing to our soils and only gantry systems can slash this to an insignificant amount. They will also introduce an increased level of precision while allowing flexibility in operations. This autorun PowerPoint

emphasises the poor sustainability of existing systems, and given that we have the knowledge and technology to make change, why are we not employing them?

We really can’t afford to go on damaging soils in the way that we are, and although small robots will provide some relief, they are and will not be the whole answer.

We really can’t afford to go on damaging soils in the way that we are, and although small robots will provide some relief, they are and will not be the whole answer.

The whole emphasis of this website is on the need for innovation in agriculture and the enormous opportunities for change. The development of drones and the increasing emergence of robots and autonomous vehicles are complementary to gantry tractor technology. They complement each other by covering the shortcomings of each, for example the challenge of using robots to harvest bulky and heavy crops such as potatoes, onions, carrots and sugar beet. On the other hand, managing crops on a plant scale is more efficiently achieved with a robot than with a gantry, although the latter is well placed to achieve the sort of operations described below.

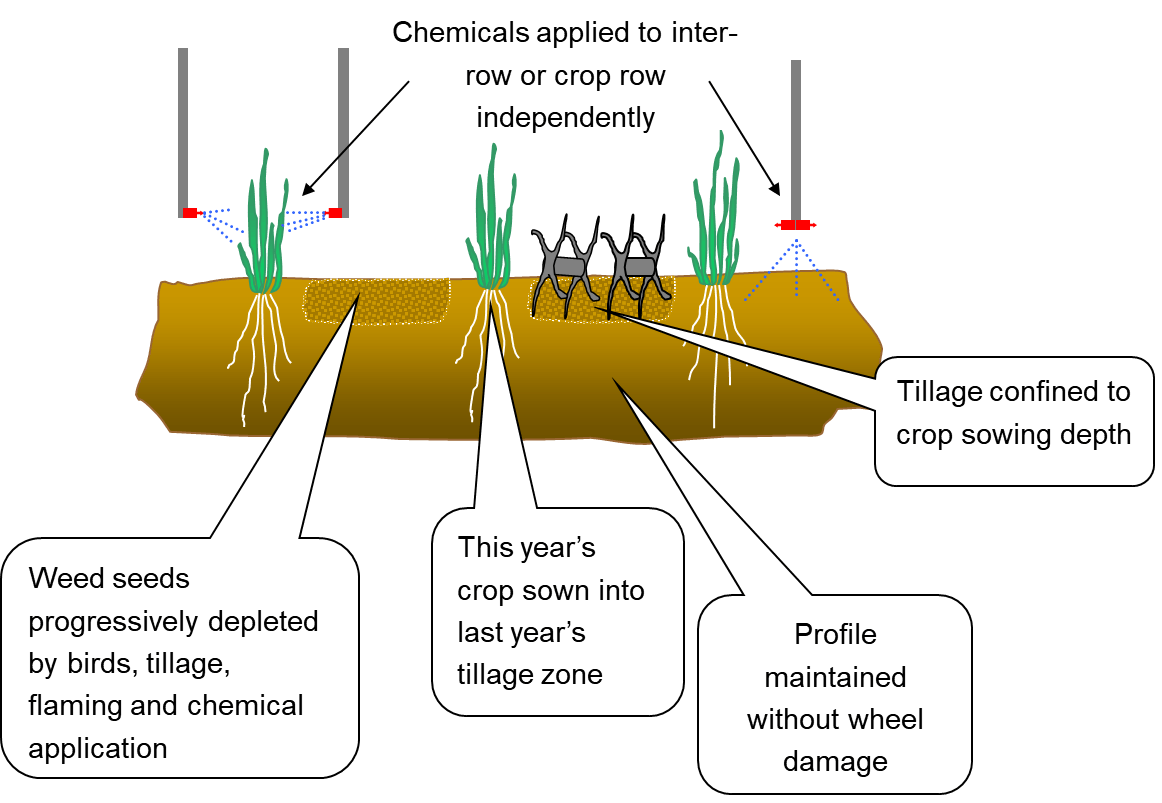

If we experience a very wet period for example, seeds destined to be sown on clay soils often remain in the barn, and mostly for the sake of being able to reliably place them just a few centimetres below the soil surface. With a gantry tractor running on permanently accessible "engineered" traffic lanes, occupying perhaps just 6% of the land, alternatives for doing this become eminently more feasible. The stable platform enables the lightest of touches on soil that is well structured from the surface down, meaning that no soil manipulation is required, only seed placement. Innovative ideas are needed to achieve this goal that would considerably reduce the risks associated with farming in these moist and often wet soil conditions. It would in addition allow farmers to make better use of delayed drilling for example to extend the range of options for weed and pest control.

Future gantry tractor envisaged

Although one can never envisage exactly how developments of this nature will progress and what will be their driving force, the anticipation is mass production of “power pods” some with and some without a driver’s cabin but all with maximum steering flexibility. In the longer term, there are likely to be more pods without cabins as full automation of field operations becomes commonplace. The space between these “pods” can be filled with all manner of designs at a range of standard widths to suit particular farming enterprises but also some standard equipment such buck rakes and front end loaders.

An interesting development is the filing of a patent application in 2016 followed by a further application in 2018 which was published under number 20200221625 in July 2020. This relates to a “Self-Propelled Machine”, details of which were shown on the original application and can be found here. As will be seen, the Dowler gantry is shown as “prior art” and I guess the track system and some other features are the principal claims under this patent.

Where to from here?

Farmers in the UK and some parts of Europe are now experiencing the advantages that controlled traffic farming can bring and some even pay lip service to gantry systems, seeing them as the ultimate way of achieving the most comprehensive and efficient CTF system.The aim of this site is to promote interest in and development of gantry tractor technology. Potential manufacturers need to have confidence that there is a market for machines of this nature and that is where the farmer reader of these pages comes in. If you are a farmer and interested in gantry tractors, please make this known by filling in your details on our CONTACT page. This won’t commit you to anything, it will just give us some indication of the amount of interest that we can present to potential manufacturers.

If you have any suggestions about how we can improve this website and its effectiveness in reaching out to potential manufacturers, we would be pleased to hear from you.